Fire Retardant Epoxy Prepregs

Notus EPFR-609

Notus EPFR-609 is a market leading fire-retardant epoxy prepreg system that combines exceptional FST performance with user-friendly handling characteristics and a long out life.

EPFR-609 is ideal for small to very large structural parts that require a Tg in the range of 100 to 120°C. It can be cured at temperatures from 85 to 120°C and is suitable for low pressure/vacuum curing processes. Notus EPFR-609 has a very long out life at room temperature (60 days at 21-23°C) and can be kept frozen for up to 18 months @-18°C.

EPFR-609 is the perfect choice for Architecture, Aerospace, Rail and other Industrial sectors where reaction to fire and low smoke toxicity are required. Notus has carried out extensive testing, with EPFR-609 complying with FAR 25.853 and NFPA 285 as well as ASTM E84 Class A and UL94 V0.

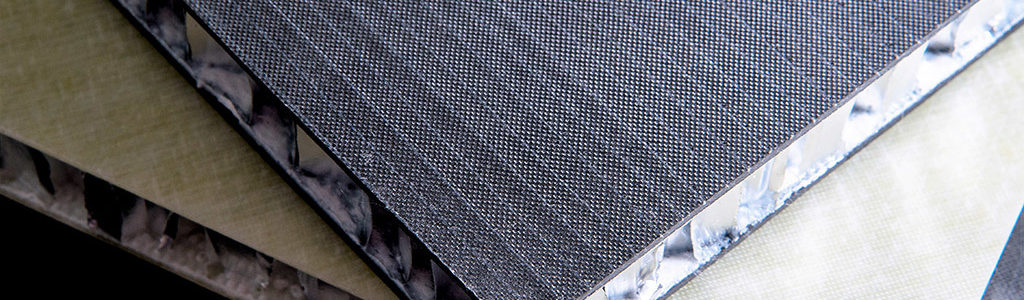

Controlled resin flow and high peel strength on honeycomb cores mean EPFR-609 is well suited to sandwich structures as well as monolithic laminates. EPFR-609 is available in all prepreg and N1-Preg formats and can also be supplied as a supported resin film.

Features and Benefits

- Exceptional fire performance.

- Low exotherm risk, even for thick laminates.

- Long out-life & shelf-life.

- High strength bonding with honeycomb and foam cores.