Notus Composites Provide 15,000m2 of Epoxy Carbon Prepreg for the World’s Largest Rolex Store

Opened in April 2018 in the Dubai Mall, the world’s largest Rolex Boutique provides an unprecedented 850 square meters of retail space which encapsulates the brand and its legacy in a truly exclusive and unique setting. Notus Composites, the innovative UAE based prepreg solutions provider, worked together with Affan Innovative Structures, Dubai to provide the prepreg materials and the uniquely designed composite panels that make up the 338m2 exterior façade of the flagship store, using more than 15,000m2 of Notus’ N1 carbon epoxy prepreg.

Building on a long-standing partnership Rolex and Ahmed Seddiqi & Sons, the Middle-East leading retailer of luxury watches and jewellery, have brought the history and know-how of Rolex to Dubai by opening a spectacular flagship store.

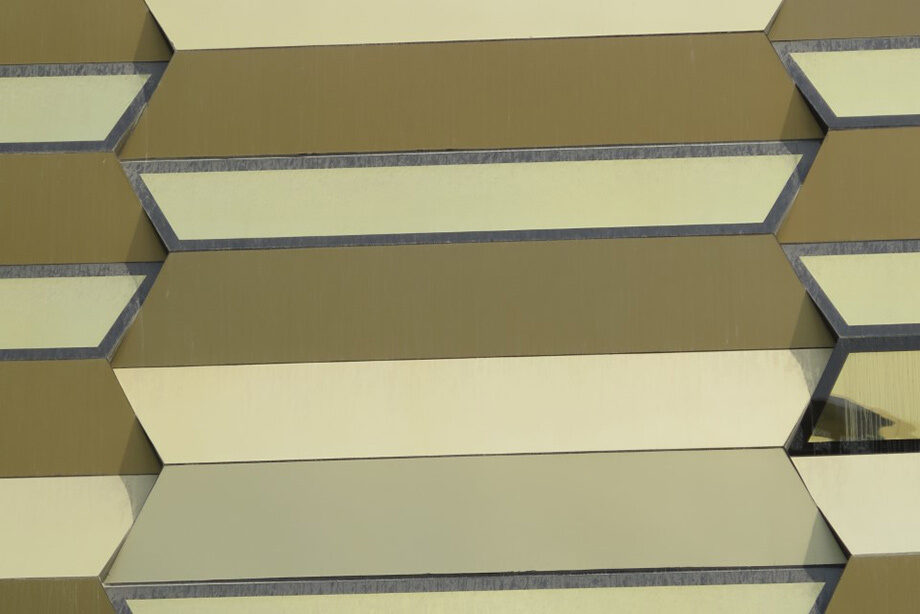

The Rolex Boutique, custom-designed by the Rolex Interior Design Department in Geneva, was created with bespoke architectural and design components. All interior and exterior design elements are inspired by Rolex timepieces themselves. The façade of the building, for example, has a fluted design which is a nod to the iconic fluted bezel that is found in the majority of Rolex watches. The alternating transparent and opaque elements of the façade bring light into the boutique and a view of the exterior from the inside.

A dedicated lift transports customers up to the upper level which is entirely dedicated to discovering the Rolex brand; its heritage, watches and manufacturing techniques. The so-called Rolex Experience even includes a theatre-style screening room!

Rolex’s philosophy can be defined by luxury, tradition, innovation and high performance. To achieve the same standard in architectural projects, their design strategies are underpinned by the latest in advanced composites technology.

The use of composite materials within the architectural market are vast. They allow creative freedom in design, due to the fact that they can be easily moulded into flowing freeform curves and shapes. With significant weight savings reducing loads on the building structure itself, composite components are also faster to install and require less lifting capacity on site. Additional advantages include less wastage, no corrosion and sustainability benefits.

One of the key requirements for composite materials to be used in architectural projects is their reaction to fire. Notus Composites, a new innovator within the prepreg market and winner of the Ras Al Khaimah Free Trade Zone Business Excellence Award for Best New Startup, is particularly known within the ME region for its products’ outstanding fire performance. Both its epoxy and phenolic prepregs have been tested and certified to all the key architectural industry standards with the epoxy FR materials having successfully passed the challenging NFPA 285 and EN13501-1 tests as well as having Class A results for ASTM E84.

With these qualifications, Notus’ N1-Preg was the natural choice when it came to the selection of materials for the Rolex Boutique.

The 338m2 exterior façade of the flagship Rolex Store comprises of 12 panels each moulded from Notus’ innovative N1- Preg system – a one sided epoxy prepreg format, approved by the DCD that reduces production hours whilst producing exceptional quality laminates.

The carbon and glass panels were laminated in a glass epoxy mould at Affan’s factory in Dubai, before glazing and gold tinted glass and silver aluminium finishes were added, and the finished panels were delivered to site for installation.

Notus’ N1-preg materials are made by applying a catalyzed resin film to only one face of a reinforcement fabric. The fabric remains dry and is not fully impregnated as a traditional prepreg would be. The pathways between the fibres of the dry reinforcement fabric allow air to be removed from the laminate as it is consolidated under vacuum, leading to very low laminate void content without the need to debulk the laminate every few plies, as would be necessary with a standard prepreg.

N1-Preg materials are especially suited to large structural components and complex laminates where the ability to lay-up and then cure the component in a single step produces large savings in both production hours and vacuum consumables. The N1- preg range includes fire retardant and low temperature curing variants and all types of unidirectional, multiaxial and woven reinforcement fabrics can be used.

“We are very proud to have contributed to this prestigious project. It has been a challenging but rewarding process, matching both the high level technical and structural requirements of the façade and providing the exceptional final finish demanded by a client such as Rolex.” comments Mihir Shah, Managing Director, Notus Composites.

With a background in Wind Energy and Automotive, Notus Composites expanded into Civil Engineering and Architectural Composites in 2016, and now includes material supply for the Dubai Museum of the Future and the 46m Carbon Fiber Palm Trees on the prestigious Palm Jumeirah in Dubai in its portfolio of projects.